WHY CH WHEELS

Advantage over regular grinding wheels

- Outlasts ceramic or resinold wheels approximately five to one on stainless and other hard-to-cut metals

- Will not load on copper, brass or aluminum

- Competitive price compared to other high quality wheels used on such metals

- The durability in a standard operation of grinding,polishing and deburring is exceptional

- 16-CH is our course ,high stock removal wheel-very durable

- 17-CH is lower stock removal –long lasting –very durable

- Smoothing the edges of punched or sheared metals cleaning and polishing contact points

- Add 16-ch or 17 ch to regular part number for ordering.

Note:

Uses

- For Application on hard or soft metals, plastics, ceramics, glass and other materials

- Standard sizes from 2” diameter to 8” diameter

- Minimum width of ¼” All sizes

- Other sizes available based on MOQ

Note:

- Metal Finishing Wheels - Softest convolute wheels used for light cleaning and surface finishing. Open mesh construction prevents heat build-up and loading. Not recommended for deburring or use on sharp edges.

- A good, all-purpose deburring wheel for the lightest finishing and polishing applications.

- The right wheel for metal prep before coating and final polishing

Coating Advantages: Aluminum Oxide

- Metal Finishing Wheels - Softest convolute wheels used for light cleaning and surface finishing. Open mesh construction prevents heat build-up and loading. Not recommended for deburring or use on sharp edges.

- A good, all-purpose deburring wheel for the lightest finishing and polishing applications.

- The right wheel for metal prep before coating and final polishing

Silicon Oxide

- Sharp abrasive grain providing high initial cut rate and penetration for work on nonferrous materials.

Deburring Wheels - General Purpose

- Harder and denser than light deburring and finishing wheels.

- Recommended for a variety of deburring, blending, and finishing applications, including removal of medium to heavy burrs, edge redressing, and deburring of punched holes on machined parts

- Loaded with additional abrasive grain for higher cut rates with less pressure, leading to extended wheel life.

- Reduced heat generation avoids smearing problems.

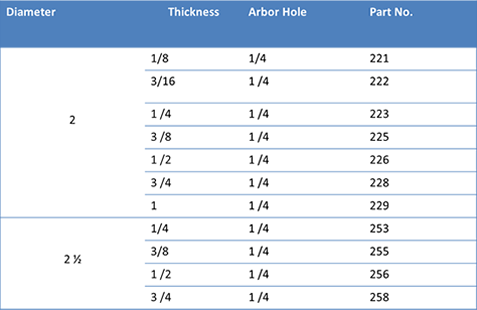

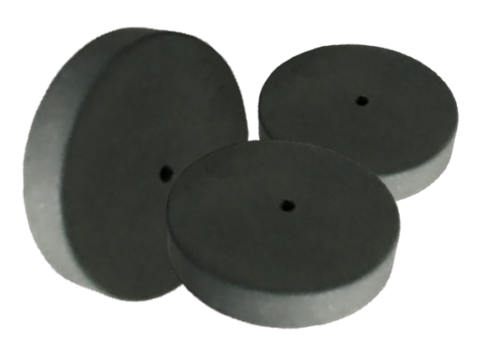

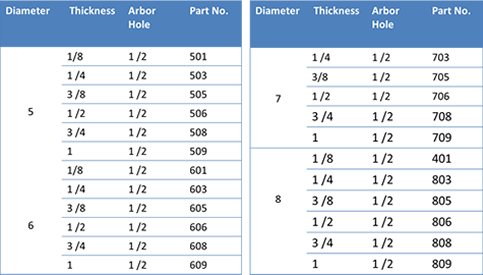

Wheel Sizes

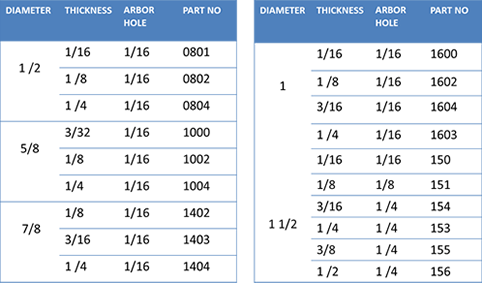

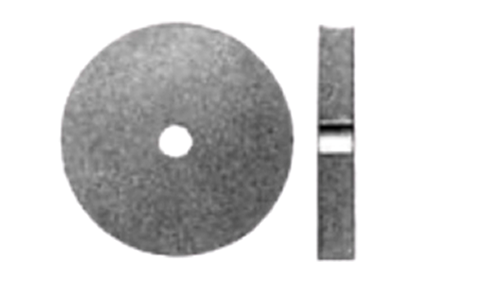

STRAIGHT WHEELS (SMALL SIZES)

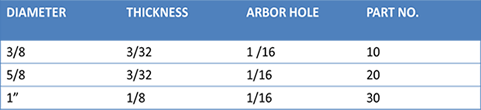

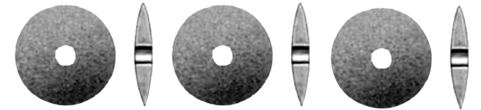

SHAPED WHEELS (TAPERED EDGES) Standard Bond Hardness

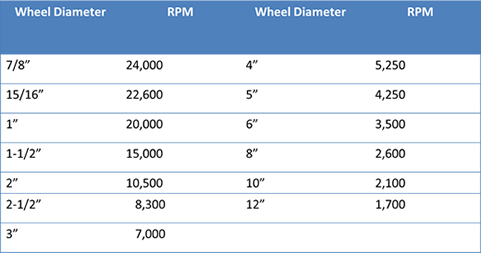

Safety Factors Maximum safe operating speeds 24,000 rpm

Depend on following : Size of grit and hardness of bond. Coarse grit – hard bond –gives fast cutting, rougher finish , Medium size grit- regular bond-…gives slower cutting , finer finish, Fine grit – soft bond… slower cutting, extra fine microfinish.