Welcome to Matzrubber website, your premier destination for high-quality rubber abrasive products. With a steadfast commitment to innovation, excellence, and customer satisfaction, we have established ourselves as a trusted leader in the rubber abrasives industry.

Read More

Harder and denser than light deburring and finishing wheels. Recommended for a variety of deburring, blending, and finishing applications, including removal of medium to heavy burrs, edge redressing, and deburring of punched holes on machined parts.

Specializing in rubber-to-metal bonding, we have been providing the highest quality custom-molded rubber products since 1954

There is a need in every industry for rubber abrasive, and the Matz Rubber Company offers a shape for every job. as a more-or-less normal

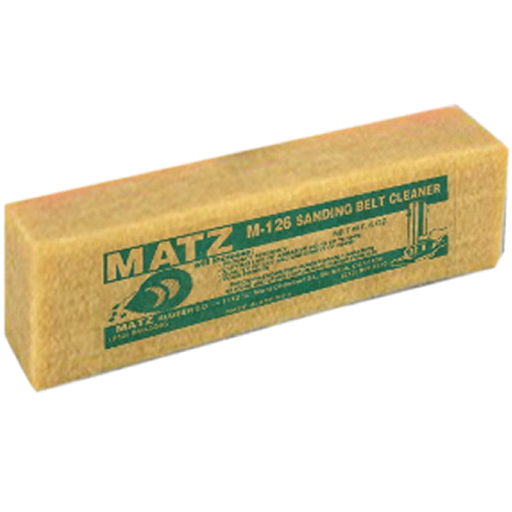

Keeping the abrasive surfaces of moving belts or rolls clean! Our products allow you such machinery to last longer and serve you better.