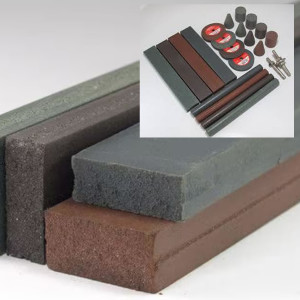

Matz products are manufactured under world-standard scientific rules and regulations. When it comes to abrasive particles and other selected materials in their semi-fluid state, for example, these are formed and molded less than 3,000 lbs. per square inch pressure into wheels, blocks, sticks and cones and then tempered and seasoned to reach a firm, tough, yet resilient texture.

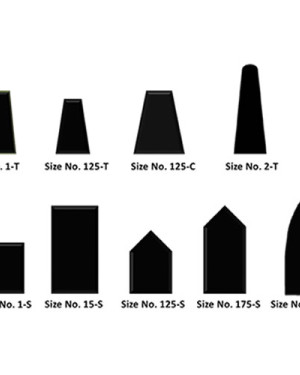

The removal of light burrs and sharp edges from die stampings and sheared or punched pieces are typical applications. It is suitable for securing a slight radius wherever required - such as on gun parts and gears.

These rubberized abrasives are used extensively on aluminum, brass, bronze, copper, nickel, steel, stainless steel, cast iron, and other iron alloys, - also on gold , silver and various grades of gemstones, doing finishing work in one operation which normally required three and four.